Maximize output and reduce production bottlenecks with intelligent automation and real-time monitoring systems.

Gain complete visibility and control over your supply chain to improve logistics, reduce delays, and enhance supplier collaboration.

Predict and prevent equipment failures before they disrupt production with our cutting-edge predictive maintenance solutions.

Ensure the highest product quality with our advanced inspection and quality control systems, reducing defects and recalls.

Challenge: Frequent equipment breakdowns leading to production delays.

Solution: Implemented predictive maintenance software.

Result: Reduced downtime by 50% and increased production efficiency by 30%.

Challenge: Inconsistent product quality and high defect rates.

Solution: Integrated AI-driven quality control systems.

Result: Reduced defects by 40% and enhanced product reliability.

Challenge: Supply chain inefficiencies causing delays and cost overruns.

Solution: Adopted supply chain optimization tools.

Result: Improved supply chain transparency, reducing lead times by 25%.

Challenge: High labor costs and low production scalability.

Solution: Automated production lines with smart robotics.

Result: Increased production capacity by 35% while reducing labor costs.

Optimize your entire manufacturing process with our comprehensive smart factory solutions, designed to enhance efficiency and scalability.

Achieve seamless coordination and control over your supply chain with our advanced management tools, reducing costs and improving delivery times.

Prevent unexpected equipment failures and reduce maintenance costs with our state-of-the-art predictive maintenance software.

Ensure the highest standards of product quality with our automated inspection and AI-driven quality assurance technologies.

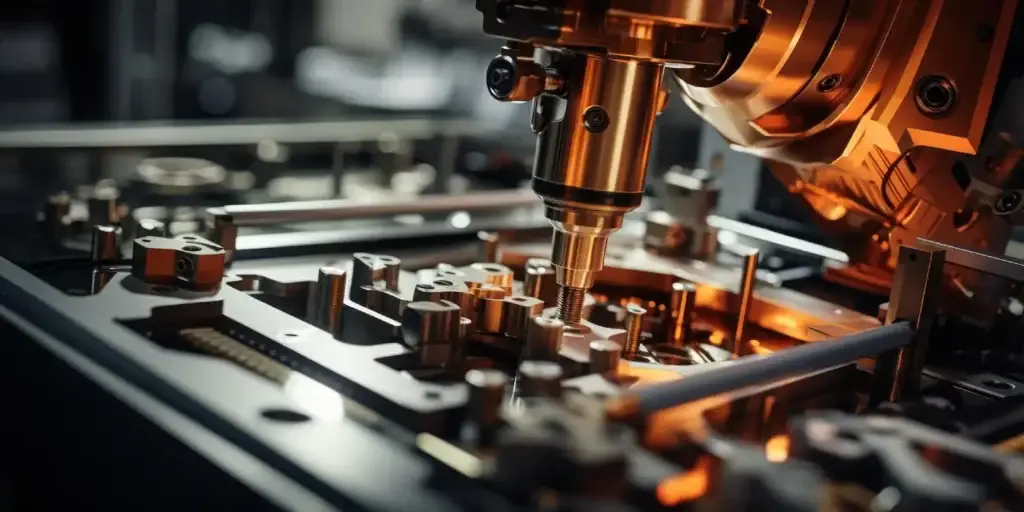

Our Industrial Automation solutions optimize manufacturing processes through advanced robotics and AI-driven systems. These technologies enhance production capacity and quality while reducing human error and operational costs.

Key Features:

See terms and conditions*